- Home

- Companies

- Fan Way Fertilizer Machinery

- Products

- Fan-Way - Model FY-SZ Series - ...

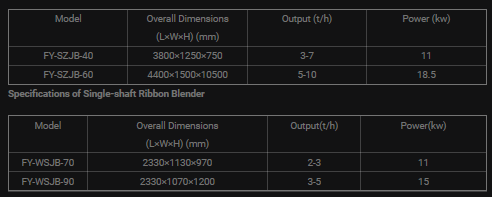

Fan-Way - Model FY-SZ Series -Horizontal Fertilizer Mixer

The horizontal fertilizer mixer, which is the new-generation mixing equipment developed by our factory, is high mixing uniformity, less material residual. This kind of fertilizer mixing machine is suitable for blending the formula feed, concentrated feed, additive premix, and raw materials of organic and compound fertilizer. There are two types of horizontal blenders: one is single shaft mixer, and the other is twin shaft mixer. They are the most common fertilizer mixing machines in organic & compound fertilizer production. As for twin shaft fertilizer mixer, it has the advantage of higher capacity and higher mixing efficiency. The two axes are in relative rotation during working so that raw materials can be evenly mixed, being widely used in organic fertilizer manufacturing.

Structure & Working Principle of Horizontal Ribbon Blender

- Rack section: All of the work body is fixed on the rack. The rack is welded by the Optimal carbon steel plate and the channel. It has arrived the requirement of specified technology and got the strict products qualified certificate.

- Transmission connection part: The motor drives the belt pulley, triangular belt, and reducer to make the main shaft rotating. The transmission reducer and the working part of

- the host are adopted the polyamide pin coupling. Easy to assembly and maintenance.

- Mixing part: The helical mixing blades which are welded on the main shaft are synchronous rotation. Stirring the materials to make them completely and evenly blending in the mixer. After a period of mixing, materials are fully mixed, materials will outflow from the outlet and be conveyed to the fertilizer granulator.

- What’s more, inside the horizontal cylinder is equipped with the rotary blades. The blades are rotating reversely. And the rotary blades are at a certain angle to stir the materials along the axial or radial direction, to make the materials mixing uniformity.

- Adopting the novel rotor structure, the minimum clearance between the rotor and shell can be adjusted to nearly zero, which efficiently decreases the fertilizer blender for saleresidue of materials.

- This fertilizer mixer is equipped with the pipeline which can add the grease into it. The overall structure of the machine is more reasonable, easy to install and attractive in appearance.

- It utilizes stainless steel spiral blade with hard steel tool bit, which is durable and good wear resistance. Thus it can prolong the service life of machine.

- With features of high mixing efficiency, materials can be fully mixed, thus improving the mixing uniformity.

- It can also crush the larger materials during mixing process.

- Low energy consumption, low noise, stable performance, easy to operation and maintenance.

- Suitable for both compound fertilizer and best organic fertilizer production