Pellenc OENOSMART - Innovative Thermovinification Process

This innovative thermovinification process significantly improves the quality of the wines and adapts the final product to consumer demand. ŒnoSm`art has been developed to meet the needs of users with its versatility. The “Flash Detente” thermovinification process works by quickly heat-treating the grapes at a high temperature, then immediately cooling them by pressure reduction.

- Rounder, fuller, fruitier wines.

- Stable colour and aromas.

- Denatures harmful enzymes (laccase, polyphenol oxidase, etc.).

- The full potential of the grapes is revealed.

- Significant reduction of defects in harvests

- Better incorporated yeasts: optimised fermentation kinetics

ŒnoSm’Art improves extraction of the grape compounds, anthocyanins, tannins, polysaccharides, and removes plant compounds.

Harvest feeding

The harvest pump with a drainage hopper allows the fresh harvest to be fed into the heating system.

Heating the harvest

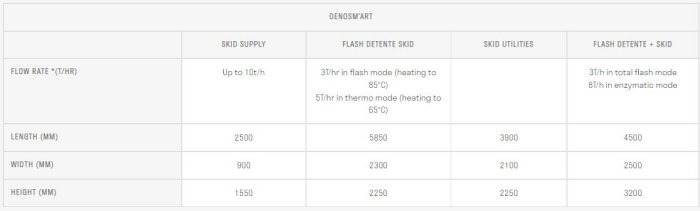

The harvest is fed into the exchanger to be heated to 65°C for thermovinification, or to 85°C for the Flash Detente process.

Flash-vacuum expansion

The heat-treated harvest is continuously fed into the flash-vacuum chamber. That chamber is subjected to a high vacuum which almost instantly cools the harvest. The steam this generates is condensed. Condensates and drained juices are reintroduced into the pump.

Easy to control

ŒnoSm’Art is controlled via an intuitive touchscreen interface which sets all the pump-operation parameters and temperatures.