- Home

- Companies

- Amandus Kahl GmbH & Co. KG

- Products

- KAHL - Fabric Wood Belt Dryer

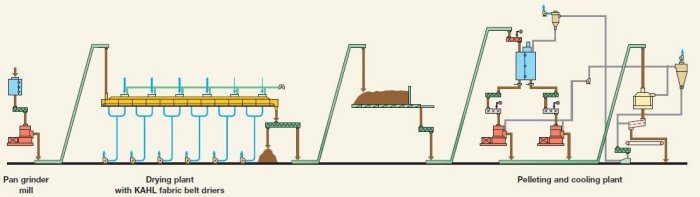

KAHL - Fabric Wood Belt Dryer

Intelligently Controlled for gentle drying of wood shavings and wood chips we have developed special belt driers ensuring: Optimum product quality amd Economic operation.

- optimum product quality

- economic operation

The plants which are individually composed of modules ensure convectional drying using hot air. Thanks to an intelligent control system, the KAHL fabric belt drier adapts to varying moisture degrees and climatic conditions.

Our fabric belt made of special plastic serves not only for transport but also as an exhaust air fan. The drying plants are also suited for high throughputs at automatic operation.

A distinctive feature of the KAHL fabric belt drier is the special, tightly woven plastic fabric belt which fulfils two functions: Transport of the product to be dried and filtration ofthe exhaust air to ensure that the legal limit value of the dust loading in the exhaust air is not exceeded. Discontinuous automatic cleaning of the belt avoids clogging of the belt openings.

Measurements by independent institutions have confirmed the observation of the limit value. The average value was less than half the admissible value. Requiring very low inlet air temperatures of less than 120°C, the drier is particularly suitable to be operated with waste heat from cogeneration. Another advantage is the low concentration of volatile organic compounds (VOCs) in the exhaust air resulting in very low odour emissions.

The newly developed product supply system allows the supply of a uniform layer of product to be dried, even if the input material and the throughputcapacities vary significantly. The product is turned over in the drier by means of specially adapted devices so that a very uniform final moisturecontent of the product is obtained.

The on-line measurement of the product moisture ensures that the drier is constantly operated with an optimum energy consumption and that the residual moisture is kept ata defined value.

Belt widths of 4 m or 6 m are possible.The efficient belt lengths availablefor drying are 11 m to 45 m.

- Convective, gentle drying by means of hot air

- Modular plant system

- Individual technical design for each product, the desired throughputand the available or desired heat source, for example hot water orsaturated steam

- Use of a special plastic fabric belt which simultaneously serves as anexhaust air filter

- Intelligent control for optimum and economic drying

- Monitoring of the relevant operating and process parameters

- Automatic operationOptional:

- Comprehensive safety system

- Easy to maintain construction

Fabric belt drier during construction

KAHL fabric belt drier: Convincing details

- Fabric belt

- Drive motors for the product supply system

- Belt control unit

- Tension station

- Product turn-over device

- Product supply unit

- Brush sealing