Falcon - Model Ø 102 - 114 - 154 -Livestock Chain Feeding Transport Systems

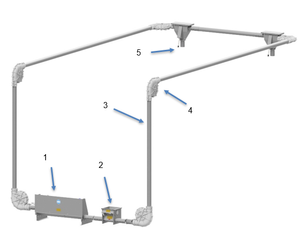

N°: Description

1: Drive unit

2: Hopper

3: Pipe

4: Corner

5: Discharge valve

The chain movement is driven by a drive unit (1). The feed is introduced into the circuit through a loading hopper (2). The pipes (3) can follow different paths thanks to deflection corners(4). The pipe sections are connected using special coupling joints. One or more material discharges can be performed at any point in the circuit via discharge valves(5), which can be either manual or automatic.

Thanks to the flexibility of the chain, spiral, and components, FALCON conveyor systems can easily handle long and winding routes, creating circuits with multiple changes in direction using just a single drive unit. During transport, friction is minimized, resulting in low power consumption. They are designed to ensure a clean working environment, free from dust dispersion, and require minimal maintenance, with quick and infrequent interventions, thereby reducing overall costs.

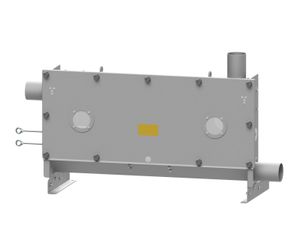

Available in painted sheet metal or stainless steel AISI 304. They can be right-hand or left-hand.

- AN with low horizontal return.

- RI with high horizontal return.

- RI with vertical return.

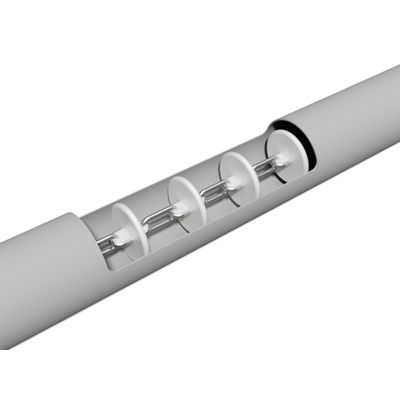

Special steel chains with molded plastic discs, highly flexible and durable, offering the following advantages:

- Wide range of applications.

- Simple and quick installation.

Available in stainless steel AISI 304 or AISI 316, or painted sheet metal

- One-way loading hoppers.

- Two-ways loading hoppers.

- Three-ways loading hoppers.

- Motorized hoppers.

Available in stainless steel AISI 304 or AISI 316, or in galvanized and painted sheet metal

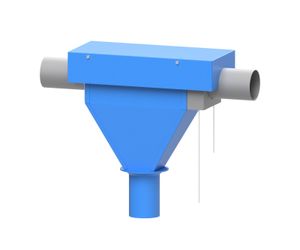

- Discharge joints

- Loading joints

- Adjustable loading/discharge joints

Available in stainless steel AISI 304 or AISI 316, or in galvanized and painted sheet metal

- Manual discharge valve

- Pneumatic discharge valve

- Electric discharge valve