Kingston Machinery

- Home

- Companies

- Kingston Machinery

- Products

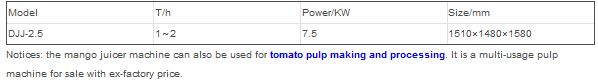

- Kingston - Model DJJ-2.5 - Mango Pulp ...

Most popular related searches

Notes when using Kingston mango elevating machine:

- fasten each bolts

- keep stable and no vibrating, keep clean

- lubrication well occasionally

- trial running 20 minutes, power off, check again, then normal running

- keep clean after each batch process

Cost effective Mango Pulp Machine

It is made of stainless steel. Operators can install the mango puree machine in a complete processing line, or use it alone.

It can be used for not only mango puree refining, but tomato, kiwi, apple, pear, date, cherry, and other fruits. In large scale mango processing, Kingston mango pulp machine is a better alternative for peel, core and pulp automatic separating.

- Net width: 400mm

- Hoisting angle ≤ 45°

- Loading capacity: 15kg/m

- Speed: max 20m/min (adjustable)

- Power: 0.75kw

- Electric motor runs through belt, making the rotor rotating at high speed.

- Mango are delivered into the processing machine via elevator.

- Vans inside the mango pulp machine push forward and crush the mango meat into pump, as centrifugal force.

- Mango pump go through sieve holes and are discharged from the outlet.

- Mango peel and core will come out from the other discharging port. The core is removed first, and then removing peel to get final mango pulp. See more detailed information on mango peeler machine here.

- The mango juicer machine can completely separate puree pure, clean and heath.