Friesla - Modular Meat Processing Systems

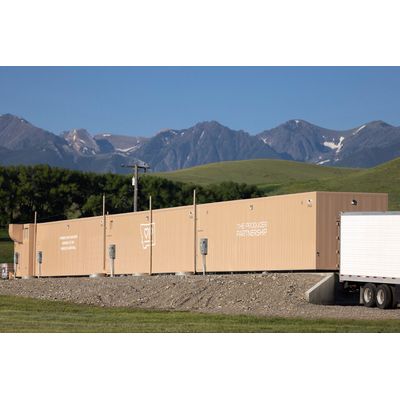

Friesla provides modular meat processing systems that empower local farmers and ranchers to maintain control over their meat processing operations. As opposed to traditional, large-scale processing facilities, Friesla's systems are made up of modular units that cover all stages of meat processing, from slaughter to packaging and sale, ensuring compliance with USDA standards. These systems are designed to be cost-effective and scalable, requiring less power and resources than conventional facilities. Additionally, they offer flexibility to expand, rearrange, or relocate as operational needs change. With integrated hardware and software for traceability and workflow management, Friesla's systems are equipped for multi-species processing including beef, bison, pigs, sheep, and more. The modular design facilitates quicker setup compared to traditional brick-and-mortar facilities. Friesla systems can be depreciated over seven years, and the company provides comprehensive design, installation, and training support to ensure operational efficiency from inception.

Consumer demand for locally-grown specialty meat products is exploding. However, the meat industry continues to consolidate under the weight of big corporations. The alarming decrease in USDA and state-inspected slaughterhouses is forcing small meat producers and processors to be beholden to the behemoths. At Friesla, we’re providing farmers and ranchers an alternative: Meat Processing Systems that enable your complete control over onsite meat processing—from slaughter to sale.

Friesla’s Meat Processing Systems are interconnected modules that enable you to knock and bleed, harvest, chill, cut and package, freeze, store, and sell meat onsite. The systems are USDA-compliant and fully integrated with your HACCP plan.

Whether you’re processing beef, bison, pork, goats, sheep, poultry, deer, or other species, harvesting your animals onsite helps to ensure meat quality, lower transportation costs, and reduce your dependence on large packing plants.

Compared to building a brick and mortar facility, our Meat Processing Systems can be expanded, rearranged, or relocated as your operations grow. The systems are more cost-effective to operate than fixed facilities, requiring significantly less power, water, and other resources.

Unlike traditional brick and mortar plants, Friesla’s Meat Processing Systems are depreciable over 7 years. The time period from concept to operations is typically significantly shorter for a Modular Meat Processing System than designing, permitting, and building a brick and mortar facility. Friesla’s systems are delivered with hardware and software to support product traceability and digital workflows. Training on system use is provided by our team.

View our Meat Processing System models below or connect with us to learn more.