Sona Machinery Limited

- Home

- Companies

- Sona Machinery Limited

- Products

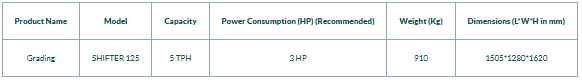

- Sona - Model 125 - Multi Grader Shifter

Sona - Model 125 -Multi Grader Shifter

Multiple sieves are stacked upon each other, with a bigger hole size at the top and then it gets smaller with hierarchy. The grain is fed from the top onto a continuously rotating machine, which in turn separates the broken rice as its diameter from the whole rice .)

Most popular related searches

USP of Multi Grader Shifter - 125

- Easy maintenance and minimum operating cost

- Inbuilt self-cleaning mechanism to ensure optimum separation

- Percentage of broken separation is adjustable

The final rice is fed into the round perforated or dimpled steel drums, which rotates continuously at the set RPM. The rice kernel of the required length gets stuck into the dimples and taken along to a required height and then dropped into a screw conveyor. The remaining rice of different length is then transferred to other drums for further grading.