- Home

- Companies

- Cabinplant A/S

- Products

- Cabinplant - Model MHW SF - Multihead ...

Cabinplant - Model MHW SF -Multihead Weigher with Screw Feeding

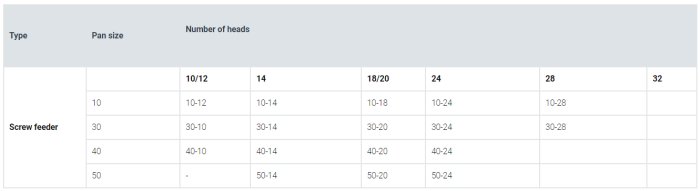

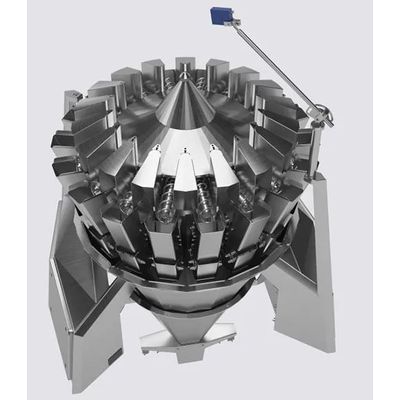

The Cabinplant Multihead Weigher with screw feeder is a unique and patented solution that is perfect for handling sticky & wet products. Speed, flexibility and precision are key parameters when optimizing your cost of production. The Cabinplant screw feeding principle has introduced the benefits of multihead weighing to processors of wet and sticky products and has made it possible for industries, in the fish & seafood, meat & poultry, fruit & vegetables and convenience food industries, to achieve higher weighing accuracy and to reduce give-away costs considerably. In addition, our customers have benefitted from a ROI of less than 18 months. The multihead weigher gives you a well-proven and reliable weighing machine. Our screw feeding multihead weighers are available in a wide range of models, and we can therefore meet your specific demands and ensure optimal handling of your products.

Proven performance

Minimizes give-away

Automates handling of sticky products

To obtain the highest possible number of combinations and achieve the highest degree of accuracy the multihead weigher is only feeding one piece of product into each pan. The sensor gate ensures optimal feeding of each assembling pan, which is ideal for packing few-piece portions.

Functionality of the multihead weigherThe multihead weigher has several functionalities which help you increase accuracy and efficiency in the production.

The multihead weigher always has continuous weighing, rotating cones on top and screw dosing time, that automatically adjusts as a function of partial portion weighing.

Furthermore rollers can be integrated between the individual channels when handling long products such as fresh fish, fillets or pasta.

Type of weighing:

- Single or multiple weighing

- Flow weighing

- Floating set-point weighing

- Single dynamic weighing (SDW)

- Dual dynamic weighing

- Give-away cloce to zero

- Specially adapted product contact materials

- Minimum noise level

- Minimum maintenance

- Easy cleaning

- Continuous weighing

- Rotating cone on top

- Automatic screw dosing time

- Rollers can be integrated

- Hygienic design