- Home

- Companies

- Henan Gate Heavy Industry Machinery ...

- Products

- Gate - Organic Fertilizer Production ...

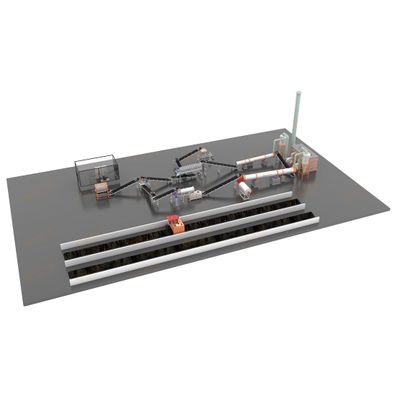

Gate - Organic Fertilizer Production Line

Bio Organic Fertilizer Production Line use bio fungi/bacteria, all organic wastes, like animal manure, agriculture wastes, municipal waste, food waste, sewage sludge, industrial organic waste, bio organic fertilizer manufacturing plant is for producing bio organic fertilizer, Capacity: 1-50 ton/hour bio organic fertilizer production process Application: small scale bio organic fertilizer production, Bio Organic Fertilizer Production plant Advantages of bio organic fertilizer machine: organic waste recycling, low investment, high return, easy operation, vast market potential, high automation/

1. Raw Material Fermentation

organic compost fermentation turner is used for fermenting and composting organic waste, such as animals & fowls manure, sludge waste, sugar filter mud, oil seed residues and straw sawdust etc. Materials can be mixed and fermented in the trough for 7-10 days. Temperature should be in 60-70℃ and moisture content should be between 40-50%.

2.Raw Materials Mixing

Fermented materials are mixed evenly together in horizontal mixer to improve fertilizer nutrient distribution uniformity and the greatest fertilizer nutrient use efficiency, which is also helpful for further granulating. The horizontal mixer machine is also suitable for feed, concentrated feed and additive premix mixing.

3. Materials Granulation

Evenly-mixed raw materials are transported into organic fertilizer mixing granulator/organic fertilizer disc granulator machine for pelletizing. The granules shape of organic fertilizer granulated by fertilizer pellet mill is round ball shape. Usually, a fertilizer polishing machine, which is designed based on flat die granulator, is used to polish the granules into ball shape with easy operation.