- Home

- Companies

- Pneumat Systems, Inc.

- Products

- Model RailSpreader - Railcar Loading ...

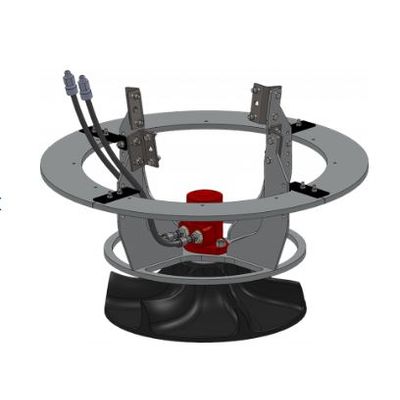

Model RailSpreader -Railcar Loading System

Railcar loading optimization technology eliminates hazardous topping-off activities and helps loadout facilities save hundreds of dollars per car.

The RailSpreader can be adapted to existing loadout configurations of all types, from a single chute to complex conveyor systems with multiple drops. It`s been proven effective on dry bulk commodities of all types.

- Dried Distiller`s Grains (DDGs)

- Soybean Meal

- Canola Meal

- Corn Gluten Meal

- Pelletized Product

- Salt

- Minerals & Metals

- Plastics

Designed to reduce voids when loading materials with a low bulk density and high angle of repose, RailSpreader railcar loading systems help loadout facilities save millions in transportation costs by optimizing their loaded fill weights.

Stop underfilling and overpaying!

During the fill process, the RailSpreader assembly is lowered into the railcar through the loading hatch. As material flows into the hopper, a hydraulically-driven slinger disk propels the material outward, allowing the hopper to fill from the outside-in without voids. These railcar loading systems are powered by a robust hydraulic power unit and explosion-proof motors and electrical components come standard. RailSpreader functions can be programmed into existing PLC controllers for fully-automated loadout operations.