Zanin s.r.l.

- Home

- Companies

- Zanin s.r.l.

- Products

- Zanin - Model TS - Rotary Drum Cleaner ...

Zanin - Model TS -Rotary Drum Cleaner for Grain Processing

FromZanin s.r.l.

The TS Rotary Drum Cleaner is engineered to efficiently eliminate large impurities from grain, making it ideal for use in pre-cleaning stages or within receiving systems at facilities like ports or railway stations. It utilizes a gravity-fed cylindrical drum equipped with a fixed screen. As grain passes through, clean particles traverse the perforations while larger contaminants are discharged separately. The screen choice can be customized based on particle size, enhancing the versatility of the cleaner. This system is available in various configurations, handling capacities from 100 to 300 tons per hour, specifically designed for wheat with a density of 0.78 t/m³ and a relative humidity of 14%, accommodating up to a 2% impurity rate. The TS Rotary Drum Cleaner blends precision and efficiency, playing a crucial role in the initial cleaning stages of grain processing.Most popular related searches

Quickly removes very large impurities in grain.

Installed upstream of a cleaning system or in receiving systems such as ports or railway stations.

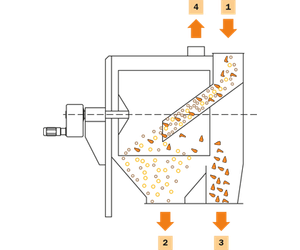

The product is fed by way of gravity into a cylindrical rotary drum covered with a fixed screen.

The clean product passes through the perforations and the large impurities are discharged at the end of the drum.

The choice of screen depends on the size of the products.

Key

1. Uncleaned product inlet

2. Clean product outlet

3. Large impurities outlet

4. Dust outlet (air inlets)

- Drum casing and uprights in thick press-formed sheet metal

- Mobile front door secured with bolts

- Screens in painted carbon steel

- Nylon screen cleaning brushes

- Extraction spiral

- Aspiration inlet

Available in various sizes and models with cleaning capacities from 100 to 300 t/h (calculated with wheat, specific weight 0.78 t/m3 - RH 14% Impurities 2%).