- Home

- Companies

- Zanin s.r.l.

- Products

- Zanin Fratelli - Model PPR - Rotary ...

Zanin Fratelli - Model PPR -Rotary Pre-cleaner for Grain

Quickly removes fine and large impurities in grain.

It must be installed at the entrance to the dryer so as not to compromise grain quality.

Homogenises the product, eliminating any lodgements and reducing power consumption.

The aspiration version reduces dust emissions into the atmosphere.

The product is fed by way of gravity into a cylindrical rotary drum covered with interchangeable perforated screens. The clean product passes through the perforations and the large impurities are discharged at the end of the drum.

The choice of screen depends on the size of the product, its humidity and the type of waste being separated.

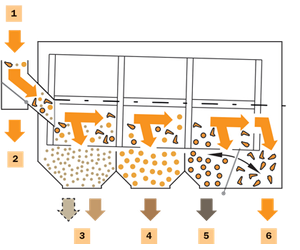

Key

1. Uncleaned product inlet

2. Product outlet (bypass, optional)

3. Clean product outlet (optional fine impurities outlet)

4. Clean product outlet

5. Clean product outlet

6. Large impurities outlet

- Drum casing and uprights in press-formed galvanized sheet metal

- Mobile side doors fitted with handle and lock

- Screens in perforated carbon steel

- Manual drum inclination

- Nylon screen cleaning brushes

- Fixed rotation speed

- Conveyor with manual regulation of discharge of large impurities

- Variable drum rotation speed

- Wooden screen cleaning rollers

- Motorised drum inclination

- Wear-resistant polyethylene sheet

- Motorised conveyor

- Control panel

Available in various sizes and models with cleaning capacities from 20 to 375 t/h (calculated with wheat, specific weight 0.78 t/m3 - RH 20% Impurities 2%).