- Home

- Companies

- Stingray Marine Solutions AS

- Products

- Stingray System

Stingray System

Our system kills salmon lice with laser while also monitoring health of farmed fish 24/7. The result is healthier fish, larger fish and better economics – on nature’s own terms.

Delousing

Stingray is a patented solution for optical delousing of salmon and trout using laser.

Lice Counting

Image-based lice counting that provides a better overview of the parasite infection.

Diagnostics

The system monitors the health of farmed fish.

Biometrics

Monitor growth in the pen 24/7.

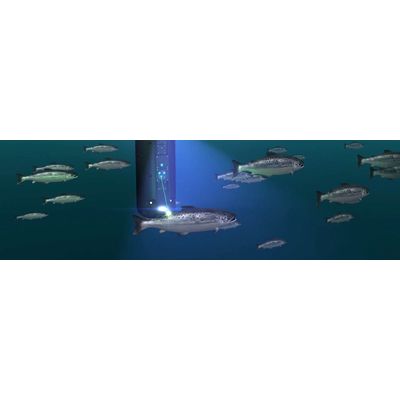

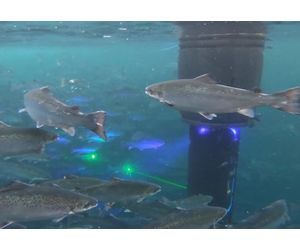

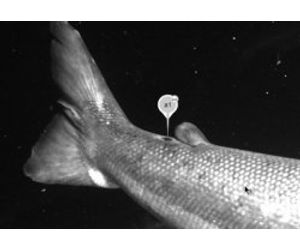

CAREFUL DELOUSING: Optical delousing with laser is a patented solution for removing salmon lice, a parasite that attacks salmon and trout. A laser pulse strikes parasites that dwell on the skin of fish while the fish swim undisturbed in the pen. The parasite absorbs the light and energy of the laser beam and suffers fatal injuries. The fish skin reflect the laser beam, and the laser treatment thereby provides a very gentle lice treatment for the fish.

The laser node works 24 hours a day throughout the year and can fire up to five pulses per second. Each time the laser node shoots a louse, it takes a picture of the fish before and after the pulse so we can be certain that the louse was hit.

At summer temperatures it takes 5–6 weeks from the egg stage until the salmon lice releases next generation of eggs into the water. After that, it takes an average of one week between each release of eggs. The rapid reproduction of salmon lice can result in exponential growth of parasites in the pen. Because the laser node continuously kills salmon lice, it prevents lice reproduction, thereby maintaining low lice levels.

WHY DELOUSING WITH A LASER?

Delousing with laser has a number of advantages compared to other delousing methods. Traditional delousing methods require fish not to be fed in the days before treatment. The actual treatment is also stressful and potentially harmful to the fish. In addition, when chemical bath treatment is chosen, chemicals may have a short-term impact on the environment.

With optical delousing of farmed salmon and trout, the fish can swim undisturbed while they are being deloused.

This means:

- No starvation before delousing

- No fish crowding

- No handling

- No chemicals

- No harm to fish or environment

- No fatalities

Fish farmers avoid losing feed days, their fish are healthier, and they save on labour and operation costs.

Laser delousing is effective against salmon lice (lepeoptheirus salmonis) but can also detect and kill sea lice (caligus elongatus) and cod lice (caligus curtus).

Image-based parasite monitoring enables proactive management of parasite treatments.

AUTOMATED: In most major salmon-producing countries, fish farmers are required to conduct salmon lice counting and report to veterinary authorities on a weekly basis. Currently, lice counting is conducted manually. This is a weather-dependent and time-consuming activity for fish farmers. Manual lice counting can be stressful and potentially harmful to farmed fish as the fish must be physically removed from the pen in order to be examined.

Since May 2018, Stingray’s customers have had access to automated image-based lice counting. Stingray’s lice-counting application detects and documents parasites in the pen so that the fish farmer can conduct lice counting from a computer at the office.

The Stingray system observes and reports welfare indicators for farmed fish and is thereby an additional decision-making support tool for fish farmers.

FISH HEALTH: Healthy fish are good economics. By monitoring signs of good and bad health, the fish farmer can apply preventive and remedial measures in good time.

Stingray’s diagnostics application uses a machine vision and advanced software to monitor vital welfare indicators for salmon and trout. The fish farmer can access the results in Stingray’s online portal.

The application will be gradually launched in 2019 with swimming speed and winter ulcers as the first indicators. More indicators will be available in upcoming releases of the application.

With Stingray’s biometrics application, fish farmers can monitor growth in each pen via Stingray’s online portal.

PRODUCTION PLANNING: Good biomass measurement reduces overfeeding which, in turn, leads to reduced production costs and waste.

Fish farmers in Norway must regularly report biomass per pen to the authorities and stay within the maximum biomass limit.

Currently, biomass estimation is primarily manual or based on calculations of feed consumption. This process is weather-dependent, time-consuming and work-intensive for fish farmers and, not least, stressful for the fish.

Moreover, current methods of biomass estimation are inaccurate with a margin of error of up to 5–10%. This often results in overfeeding of the salmon as well as higher production costs and greater environmental impact.

In 2019, the first version of Stingray’s application for biometrics will be launched, which will make it possible to monitor the growth on an ongoing basis.

Fish farmers will get more representative biomass measurements, which will will save time, reduce over-feeding and leave a smaller environmental footprint.

At Stingray Online fish farmers can obtain updated and secure production data from each pen. The user portal provides better insight into the production and ensures good documentation and more precise decision-making for fish farmers.

PORTAL: All data collected from the customer’s pens is analysed and presented in the customer’s own customer portal.

Stingray Online gives the fish farmer updated data and a live camera feed from all pens in which the Stingray system has been installed.

Fish farmers can obtain, for example, information about uptime, lice count, number of laser pulses, service information, essential documentation and image/video documentation of lice shots.

All users are certified annually through the web-based training platform Stingray Academy. Stingray Academy provide all users e-learning and easy access to information from the user manual.