Franquet - Model X-Load S6 -Sugarbeet Harvest Loader

A range of high performance loaders by Franquet. The new X-LOAD S6 Franquet loader is the perfect compromise between beet care and thorough cleaning. You gain independence by retaining the versatility of your tractor all year round! The site gains in comfort, grip while limiting compaction by keeping the usual tire mounting of your tractor.

The new X-Load range complements the X-Beet :

- either associated directly behind the tractor for a simultaneous collection with the uprooting,

- is broken down to allow drying time between lifting and loading.

The X-LOAD loader, a simple, robust machine, consuming little power

The X-Load S6 is attached to the tractor lift arms.

In the transport position: the lift is raised, which provides generous ground clearance for the machine.

In the working position: the lowered lifting allows the pick-up to ensure optimal monitoring of the ground in the floating position.

Franquet endeavored to design a simple, robust machine that consumes little power. This is why the cleaning circuit is exclusively mechanical, and driven directly by the tractor universal joint.

An independent hydraulic unit rotates the spreader, the elevator conveyor, the hopper filling conveyor and the hopper emptying conveyor.

Only the secondary hydraulic functions require a single hydraulic distributor on the tractor:

- wheel direction,

- machine tilt,

- pick-up height,

- opening and closing of the drain elevator,

- height of the spreader,

- boom cylinder.

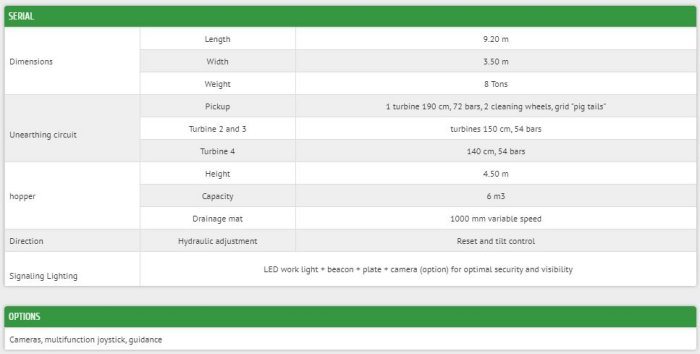

The beet swath pickup in the X-Load S6 has a 190 cm rimmed turbine with 72 bars. Two pneumatic cleaning wheels prevent the turbine from loading soil even in difficult conditions.

The soil depth of the turbine is adjustable in relation to the soil shoes, to adapt to the conditions of the plot.

The turbine is closed by a "pigtail" grid providing significant digging up as soon as the beets enter the machine.

The pick-up is optionally controlled by the multifunction joystick which offers ease of control for maneuvers at the headland.

The pick-up up and down function is synchronized with that of the leaf spreader: when the driver lowers the pick-up, the latter goes into floating position and the leaf spreading reel goes down and starts to rotate a few seconds later.

The cleaning circuit of the X-Load S6 consists of 4 turbines mechanically driven by the tractor for maximum reliability and minimum power consumption.

- Turbine 1: 190 cm with 72 bars

- Turbine 2 and 3: 150 cm with 54 bars

- Turbine 4: 140 cm with 54 bars

The speed of the turbines 2, 3 and 4 is variable by simply changing the gimbal position.

The inclination of the cleaning circuit is variable thanks to the jacks on the wheels.

In difficult conditions the rear of the machine is able to rise making the cleaning path more aggressive and therefore more cleaning.

Following the turbines, the beets are transported by a basket elevator, giving priority to root care, and by a 650 mm elevator belt to the hopper.

As an option, the basket lift can be replaced by a double belt (synchronous or asynchronous) necessary in particularly difficult conditions.

Large capacity hopper and quick emptying!

The large hopper of the X-Load S6 makes it easy to travel more than 160 meters in beets at 100 T / ha: as practical for opening fields as for changing the bucket.

The 650 mm hopper filling belt optimally fills the hopper.

This position also makes it possible to reduce the height during transport:

- In the low position for a limited fall height of the beets when the hopper is empty.

- In the high position to obtain maximum loading of the hopper.

The large 1000 mm variable speed emptying belt allows complete emptying of the hopper in 45 seconds.

Agile and handy

The X-Load S6 is fitted with steered wheels with automatic reset as well as an articulated boom on the cylinder, giving it unmatched maneuverability even in the event of reduced headland.

The steered wheels are also equipped with jacks acting on the height of the machine.

It has a significant ground clearance useful for sometimes uneven field entrances.

The multifunction joystick (optional) combines all of these functions.

Impeccable leaf distribution

The spreader on the back of the X-Load S6 spreads the sheet swath formed by the X-Beet. In the field it is synchronized with the pick-up, thus limiting the number of actions at the headland. A lock allows safe transport.