Delpimak - Model Z -Tilting Type Vertical Elevator

Pulses, seeds, wheat etc. It is a machine used to transport agricultural products and highly fragile industrial raw materials from one point to another during the process or during packaging. It is preferred because it does not damage the product during transportation.

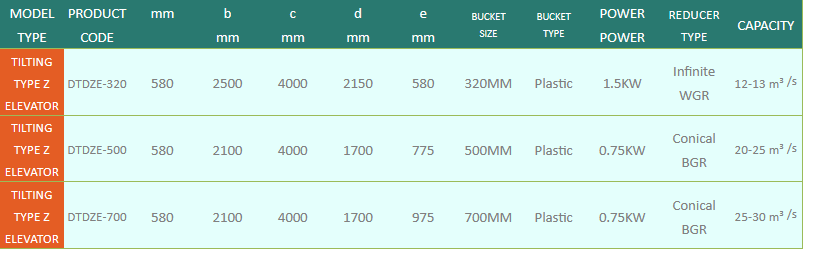

It offers very efficient solutions in complex production lines due to its ability to carry simultaneously in horizontal and vertical axes. Horizontal and vertical axis lengths can be manufactured in desired dimensions. It is called "vertical z elevator" because it is designed to rise at a 90° angle to the vertical axis. The reason why it is designed to move at this angle is that it offers healthy solutions in businesses where the working area is narrow.

The most important difference from standard z elevators is the ability to discharge product at more than one point. In processes where more than one z elevator is needed, a solution can be produced with a single elevator. Special automation and air installations are needed in multi-pour systems. The pouring process is done with the help of “pneumatic elements”.

Specially designed buckets are attached to the endless chain system that runs along the gears inside the machine. The product poured into buckets is poured at the pouring point by rotating with special pouring apparatus. Since the product delivery process must be homogeneous, it is generally produced with vibro feeder chambers. In processes with homogeneous (smooth and constant) flow, it can also be operated with product collector (chute) elements.