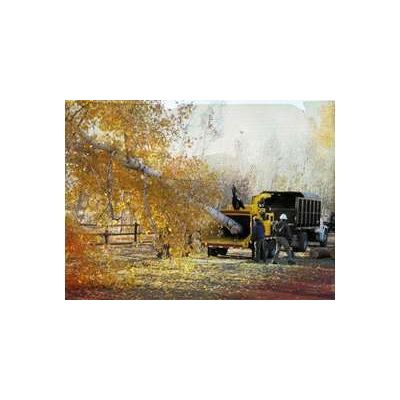

Vermeer - Model BC2100XL -Brush Chipper

Engineered for high volume processing, the BC2100XL bullies through wood waste up to 21”/53.3 cm in diameter. The combination of the exclusive Vermeer SmartCrush feature and two patent-pending horizontal feed rollers produce a theoretical 10,000 lbs/4,536 kg of combined pulling force. Choose from one of three Cummins diesel engine options. Add on the optional winch to lift up to 4,000 lb/1,814 kg logs directly onto the feed table.

- Improve productivity with the SmartFeed system, which monitors engine rpm and senses jams, automatically stopping or reversing the rollers as needed.

- Provides operator safety with a 60.5”/153.7 cm feed table for extra distance and exclusive bottom feed stop bar system.

- Protect your investment with a 3-year/3000-hour extended limited warranty on drum housings, cutter drums, shaft and ring-feeder hubs in addition to the 1-year/1000-hour Vermeer equipment limited warranty.

- See your Vermeer dealer for comprehensive service and genuine Vermeer replacement parts.

With three engine options, this brush chipper delivers the power to tackle tough land-clearing jobs. Two patent-pending horizontal feed rollers, a tensioned belt-driven cutter drum, and the largest feed table in its class turn that power into productivity. Plus, you can keep working longer with easy, low-cost maintenance.

More than just tough, this brush chipper can process trees and limbs up to 21" (53.3 cm) in diameter and has several exclusive features that make it a smart choice as well. The BC2100XL feed rollers boast 10,000 lb (4536.9 kg) of theoretical combined pulling force, giving the operators the ability to process “whole trees” that have limbs and branches attached to the main trunk of the tree. It also helps reduce the need for repositioning the material while being fed.

Heavy-duty tandem torsion axles provide reliable off-road jobsite performance as well as decreased ground pressure for softer conditions compared to single axle designs. Taillights are mounted high above and to the sides of the infeed table and set back from the feed table for protection and improved visibility in comparison to lower-mounted designs.

Powerful, smart and productive. It’s a legendary combination you can believe in.

Three Cummins diesel engine options to match most jobsite needs. Options include 215 hp (160.3 kW), 250 hp (186.4 kW), or 275 hp (205.1 kW).

SmartCrush puts the pressure on branches. Once the upper feed roller raises for four seconds, it will automatically increase down pressure on the material being fed. This allows the upper feed roller to easily climb onto large forked material before the increased down pressure is applied for maximum pulling force.

The lower feed roller is offset from the upper feed roller by 11" (27.9 cm). Material is easily pulled to the upper feed roller, so there is less need to manually raise the upper feed roller for larger diameter material.

An optional patent-pending winch eliminates the need to drag large material to the chipper. The 150` (45.7 m) winch line can handle material up to 4000 lb (1814.9 kg), making it easy to lift logs directly onto the feed table. In addition the winch can also be hydraulically raised out of the way to allow operators to feed the unit using a loader.

Optional remote control lets one person do the work of two. Operate one machine to load while still maintaining control of the chipper. The remote control operates forward, reverse and stop functions of the feed rollers, restarting the feed rollers, engine throttle, engine stop, crush boost for the upper feed roller and hydraulic discharge chute positions (if equipped).

The SmartFeed system increases operator productivity and reduces strain on vital engine parts. A patented feedsensing control system monitors engine rpm and automatically stops or reverses the rollers when feeding larger, hardwood material. Plus, it senses feed-roller jams and responds by automatically shifting material back and forth, reducing the need for manually manipulating the control bar.

General

Weight (with outriggers): 15,000 lb (6804 kg)

Weight (without outriggers): 14,700 lb (6667.8 kg)

Weight (with outriggers and winch): 16,380 lb (7429 kg)

Operational length (tongue extended): 21.6` (6.6 m)

Width: 95.8" (243.2 cm)

Height (standard chute): 116.5" (295.9 cm)

Height (adjustable chute minimum): 110" (279 cm)

Height (adjustable chute maximum): 11.3` (3.5 m)

Engine Options

Make and model: Cummins QSB 6.7L

Horsepower: 215 hp (160.3 kW), 250 hp (186.4 kW), or 275 hp (205.1 kW)

Max torque:

215 hp (160.3 kW): 655 ft-lb (888.1 Nm)

250 hp (186.4 kW): 728 ft-lb (987 Nm)

275 hp (205.1 kW): 730 ft-lb (989.8 Nm)

Fuel type: Diesel

Number of cylinders: 6

Cooling medium: Liquid

Electrical

System voltage: 12 V DC

Capacities

Fuel tank: 65 gal (246.1 L)

Hydraulic tank: 24 gal (90.9 L)

Chassis

Frame: C channel, 2.5" x 4.5" x .038" (6.3 cm x 11.4 cm x 0.1 cm)

Tires: 235 / 75R17.5 load range J

Axle / Suspension: Dexter tandem torsion

Hitch: 3" (7.6 cm) pintle

Cutting System

Drum system: Spherical roller bearings

Drum speed: 1084 rpm

Drum-size opening: 21.5" x 28" (54.6 cm x 71.1 cm)

Knives: 4 knives

Feed / Discharge System

Chipping capacity: 21" (53.3 cm)

Feed table height: 39" (99 cm)

Feed table length: 60.5" (153.7 cm)

Feed table width: 72" (182.9 cm)

Max feed speed: 100 fpm (30.5 m/min)

Number of feed rollers: 2 horizontal

Discharge height: 116.5" (295 .9 cm)

Discharge chute rotation: 270°

Options

Adjustable height discharge chute

Remote control

Hydraulic outriggers

Hydraulic chute controls

Hydraulic winch