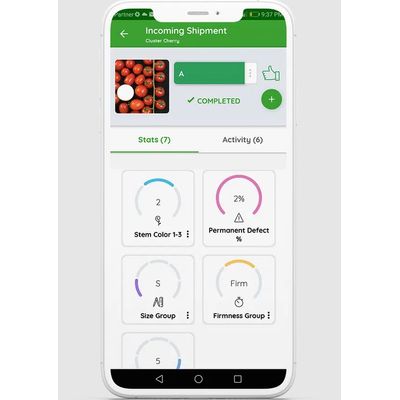

It’s as simple as downloading the quality control application and taking a photo. The Clarifruit qc mobile app is suitable for both iOS and Android devices, and free to download. Simply take a photo of the fresh produce and our patented proprietary computer-vision and machine learning technology engine will analyze external attributes, including color, stem color, and size. Our quality standard algorithm leverages our ever-growing Big Data library, that contains more than 100,000 photos and produce attributes with similar characteristics. Our fresh produce quality control app can also be easily integrated with third-party hardware to access internal attributes such as degrees brix from a refractometer, pH, and firmness from a durometer.

Clarifruit

Automated Platform

FromClarifruit

Clarifruit is building the world’s first cloud-based solution that automatically collects your fresh produce quality control data and analyzes it, delivering objective and consistent QC inspections, real-time visibility, and a superior QC management experience. Our end-to-end quality control solution has three main components: Front-End Mobile App, Management Dashboard, Big Data and Analytics Platform. Together, they enable you to optimize quality control across your entire produce supply chain.

Most popular related searches

fresh produce quality

fresh produce

produce quality

vegetable handling

fruiting vegetable

BRIX refractometer

BRIX

fruit handling

Empowering Growers, Marketing Companies, Wholesalers & Retailers to Make Informed Decisions about Fresh Produce Quality

Automatic and easy-to-use

Quality control app that can be used on any device, by anyone, at any time, and from anywhere.

Standardize QC processes

Facilitates standardized fresh produce quality control processes both within an organization and at multiple points in the supply chain.

Increase inspector productivity x3

Fast and automated fresh produce quality control increases inspector productivity across the supply chain.

Objective and consistent results

Automatic analysis of real-time data removes human bias errors from fresh produce QC processes.

Reduce rejections

Ensure quality corresponds with customer specs through high-quality data and auto-generated reports to reduce rejections and price negotiations.

Maximize revenue per customer

Better match quality to customer demand to optimize revenue opportunity per customer.