Comact products

Sawmill Equipment – Mechanical - Log Handling & Processing

Comact - Model SWF-300 - Stem Wave Feeder

Specially-designed for optimized bucking. Throughput of up to 40 stems per minute. For stems of up to 80′ (24 m) in length and 42″ (107 cm) in diameter. For all species. Efficient handling of curves, knots, limbs, etc.. Easy, low maintenance. Sturdy built. Energy savings. Patented design.

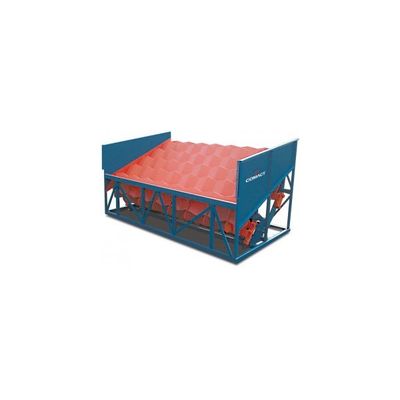

Comact - Model LWF-300 - Log Wave Feeder

Over 600 in operation worldwide. Ideal for all applications requiring efficient log feeding. Efficiency rate of nearly 100%. Throughput of up to 55 logs per minute. For logs of 2″ to 42″ (5 to 102 cm) in diameter. For all species. No need for human intervention. Log spacing control available. Efficient handling of the following defects: curves, knots, limbs, etc.. Easy, low maintenance. Sturdy built. Energy savings. Patented design.

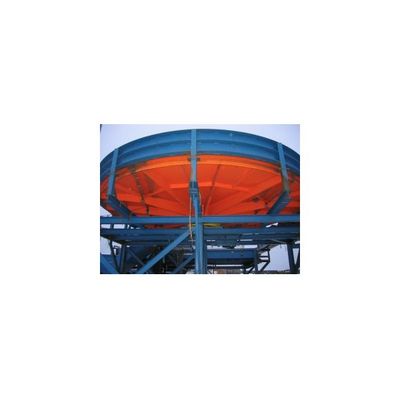

Comact - Model LTT-100 - Log Turntable

Log orientation for small end first in the process. Rotation ensured at 100%. Automatic operation. Quiet, shock-free operation. Customized design for each application. High throughput. Sturdy built. Low maintenance. Reliable operation. Guaranteed performance.

Sawmill Equipment – Primary Breakdown

Comact - V-Flight Measuring Conveyor

V-flight conveyor for log stability during measurement. Lubricated, guided chain to prevent unwanted shifts. Special design allowing acceleration and deceleration without slippage. References for applications above 650 fpm (200 m/min.). Ideal for measuring in these applications: bucking, log sorting, and sawing lines. Sturdy, proven design. Electrically driven by drive chain or driveshaft

Available with variable speed.

Comact - Optimized Log Turner

Heavy-duty frame for large logs and high speed. Designed for logs from 2″ to 30″ (5 to 76 cm) in diameter. Vertical movement controlled by servo-cylinders. Roll opening and closing controlled by servo-cylinders. Perfect log gripping during rotation process thanks to quad-roll configuration. Rotation accuracy guaranteed in purchase contract when controlled and optimized by Comact. Minimal impact of knots and butt flares on rotation accuracy. Designed to operate equally well whether small end or butt end of log is first.

Sawmill Equipment – Secondary Breakdown

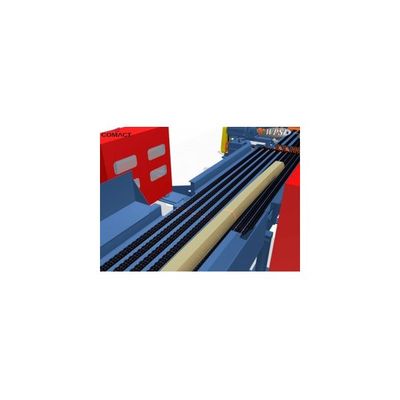

Comact - Cant Optimizer Conveyor

Conveyor for linear cant scanning at secondary breakdown. Guided, lubricated chain to prevent unwanted shifts. Roof-top chain for stopping and accelerating cants without slippage. References for applications above 650 fpm (200 m/min.). Ideal for measuring in TBL3 or wiggle-box applications. Sturdy, proven design. Electrically driven. Available variable speed.

Comact - Model TBL2 - Optimized Sawing Equipment for Short Material

Sawing With Reduced Spacing: Optimized cant sawing by automatically following cant shape; Spacing between each cant reduced to 3′ (90 cm) for peak performance; Integrated finger pickers for slab elimination at sawing equipment outfeed; Operating speed of up to 650 fpm (200 m/min.); Cant positioning during linear movement; Thin-kerf guided saws; Heavy-duty built for the North-American market; True-shape optical measuring scanners and complete sawing optimization; Easy access for equipment observation and maintenance.

Sawmill Equipment – Electronic - 3D Linear Optimizers

Comact - Model 3DPro - Scanner

One model for all linear equipment. Quick replacement. Pre-calibrated, no setting required. Unrivaled reading accuracy. Fast scan rate (up to 5000/second). Compact. Three-year warranty.

Sawmill Equipment – Electronic - Expert Linear Optimizers

LogExpert - Defect Detection Optimizers

Designed to capture log or cant ends, the Comact LogExpert determines, right upon sawing, the optimal cutting pattern to increase product value.

Comact - Cant Faces Scanner

Cant optimizer with color and geometric vision for enhanced secondary breakdown profitability.