Comact products

Sawmill Equipment – Secondary Breakdown

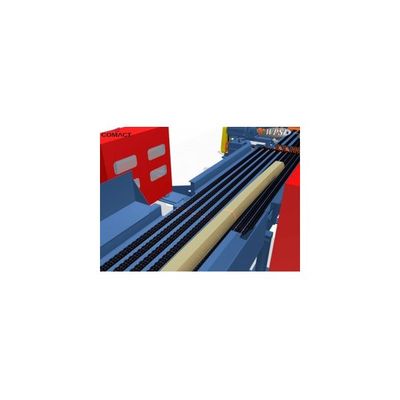

Comact - Cant Optimizer Conveyor

Conveyor for linear cant scanning at secondary breakdown. Guided, lubricated chain to prevent unwanted shifts. Roof-top chain for stopping and accelerating cants without slippage. References for applications above 650 fpm (200 m/min.). Ideal for measuring in TBL3 or wiggle-box applications. Sturdy, proven design. Electrically driven. Available variable speed.

Comact - Model TBL2 - Optimized Sawing Equipment for Short Material

Sawing With Reduced Spacing: Optimized cant sawing by automatically following cant shape; Spacing between each cant reduced to 3′ (90 cm) for peak performance; Integrated finger pickers for slab elimination at sawing equipment outfeed; Operating speed of up to 650 fpm (200 m/min.); Cant positioning during linear movement; Thin-kerf guided saws; Heavy-duty built for the North-American market; True-shape optical measuring scanners and complete sawing optimization; Easy access for equipment observation and maintenance.