EB Equipment Limited products

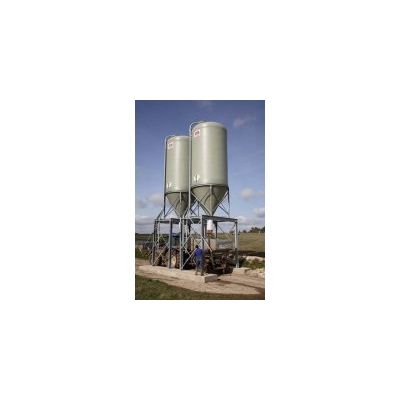

EB - Silos

EB were the first in the UK to develop the production of silos in GRP (glass reinforced plastic) and have continued to lead the field ever since, developing unique processes to produce the only UK GRP silo, which are of one piece construction, totally seamless, totally watertight. Continuing investment and research has resulted in one of the most advanced silo and tank production facilities across Europe.

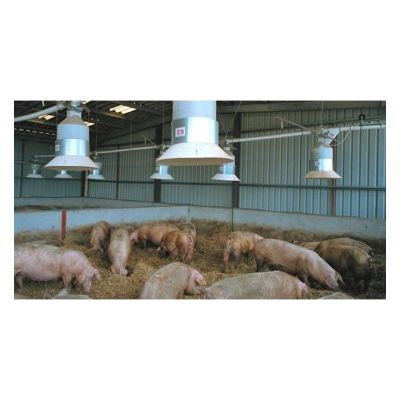

EB - Pig Feeding Systems

EB’s original patented design of 1963, awarded bronze medal in 1965, is still the industry standard and although it has gone through design modifications as new materials and new technology are developed, it is still the tried and trusted formula. The sow dumper automatically dispenses (by weight) predetermined amounts of food onto the straw bedding, thus satisfying the natural desire of pigs to root for their food, roam, rest and sleep in groups. All sows have an equal opportunity to feed, avoiding bullying and reducing stress as the sows are fed simultaneously without noise and fuss, automatically.

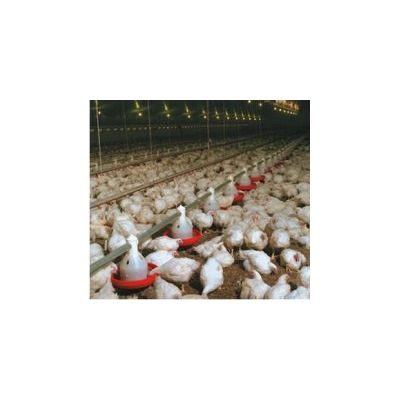

Winchable Poultry Feeding Systems

The broiler market demands a fully suspended, winchable feeding system, with round pans set at intervals allowing free movement of birds. The EB winchable pan system achieves dramatic reductions in labour and running costs by virtue of its pan size. Most pan feeding systems set the pans at 750mm centres, with a pan circumference of approximately 1040mm, as opposed to the EB pan which is 1280mm - that is 23% greater in circumference at the pan. However, when the position of the bird when eating is taken into consideration it is accepted that the EB system gives the same linear feeding area, at 1000mm centres. The reduced number of pans saves 25% in adjustment time, cleaning and maintenance.

Free Range and Game Feeding System

The concept for the 90’s was the production of eggs from birds in loose-housed systems, i.e free range. Also in recent years the demand for game birds has increaseed to a level where large-scale production units required equipment more specific to their requirements. EB has many years of experience in the design and manufacture of drinker and feeder systems for loose housed/free range birds, awarded a medal in 1958, followed by periodic accolades up to the present day.

Overhead Feeding Systems

In these days of totally enclosed houses and high stocking densities, EB Equipment have recognised the need for an alternative to the conventional round the house chain powered, low capacity systems. The use of two augers transports food directly to the stock, reducing damage during house clearing and cleaning, saving time on systems that need stripping and clearing. The auger tubing, pans and assembly are made of durable polypropylene and exceed all known poultry house hygiene and cleaning regulations.

Agriculture - Silos

EB - Centre Discharge Silo

Centre Discharge Silos are designed for use with automated conveying systems. Offering up to 100 tonne capacities with a discharge height of 800mm. Bespoke sizes are also available to suit individual needs.

EB - Side Discharge Silo

All the advantages of Centre Discharge Silos, with the added benefit of a manual discharge at the side of the structure, allowing you to discharge into loader buckets, bags, hoppers or through building walls. The design of the side discharge configuration is to promote optimum flow at an even discharge rate without separation.

EB - High Side Discharge Silo

EB Equipment High Side Discharge silos are specifically designed for manual discharge into diet feeders. Featuring a standard discharge height of 2.8m, using a ground operated gate valve. The design of the discharge configuration is to promote optimum flow at an even discharge rate without separation.

EB - Discharge Drive Under Silo for Tractors

Drive Under Silos offer a high discharge outlet and easy drive through access for a tractors / trailers, TMR feeder, wagons etc. Allowing higher storage capacities with less ground space and a lower overall height.

EB - Fabric Silo

EB Equipment Fabric silos are designed for internal storage. Supplied in kit form, with components which can pass through a standard doorway, and can be assembled inside rooms with a minimum height of 2.5m. The silo layout can be customised to allow easy access for barrows, bagging-off, snackers or automated conveyors.