- Fruit Harvesting Technology - Fruit Picking Machines

- Fruit Harvesting Technology - Fruit Picking Machines - Large Crate Trolley

- Fruit Harvesting Shakers

- Shakers - Hydraulic Trunk Shaker

- Fruit Sweeper/ Fruit Blower

- Rollblitz

- Fruit Sorting

- Nut Processing - Large Amounts - Transport of Nuts

- Nut Processing - Large Amounts - Washing Nuts

- Nut Processing - Large Amounts - Dividing and Separating Nuts

- Nut Processing - Large Amounts - Sorting Nuts

- Nut Processing - Large Amounts - Drying Nuts

- Nut Processing - Large Amounts - Measuring Moisture

- Nut Processing - Large Amounts - Calibrating Nuts

- Nut Processing - Large Amounts - Cracking Nuts

- Nut Processing - Small Amounts - Nut Washing

- Nut Processing - Small Amounts - Nut Calibration

- Nut Processing - Small Amounts - Nut Cracking

Feucht Obsttechnik GmbH products

Nut Processing - Large Amounts - Calibrating Nuts

Feucht-Obsttechnik - Hand Stencil

Using the hand stencil, a size can be selected to determine the calibration sieve. The calibration of the nuts is a decisive step for the further processing of the walnuts. The walnuts must be sorted into various sizes in order to achieve a very good drying and cracking result. For larger quantities, automatic calibration machines are used. These machines work with calibration drums with holes of different sizes. Using the rotating calibration sieves, the walnuts are then calibrated in size classes.

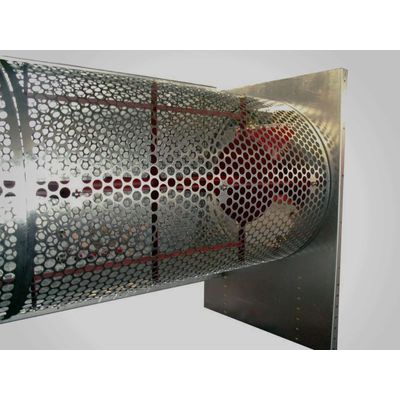

Feucht-Obsttechnik - Cylindrical Nut Calibration Machine

Calibrate from 100 kg to 1,000 kg nuts per hour. The nut calibration machine has a calibration drum. This can sort the nuts in the same operation according to the same or 2 different sizes (optionally also up to 4 sizes). In addition, the sorting sieve can be changed easily and quickly. Calibration sieves are available for every diameter. The working and total height are variably adjustable. The drive of the cylindrical calibration machine is via a worm gear or with an elastic coupling. Using an optional plastic sieve, chestnuts can also be gently calibrated.

Feucht-Obsttechnik - Washing and Calibration Universal Machine

The universal machine for cleaning, calibration, and dividing walnuts. The washing and calibration machine cleans and sorts the nuts according to size. Thus, up to 95% of the raw shells are separated from the nuts. For the cleaning, a wash drum (oval design) is used. The roller / drum is then exchanged with a round hole sieve for calibrating the nuts. You can choose between two calibration values. It is driven by a standard drill. Optional with feeding of the nuts or electric motor with 230V.