- Fruit Harvesting Technology - Fruit Picking Machines

- Fruit Harvesting Technology - Fruit Picking Machines - Large Crate Trolley

- Fruit Harvesting Shakers

- Shakers - Hydraulic Trunk Shaker

- Fruit Sweeper/ Fruit Blower

- Rollblitz

- Fruit Sorting

- Nut Processing - Large Amounts - Transport of Nuts

- Nut Processing - Large Amounts - Washing Nuts

- Nut Processing - Large Amounts - Dividing and Separating Nuts

- Nut Processing - Large Amounts - Sorting Nuts

- Nut Processing - Large Amounts - Drying Nuts

- Nut Processing - Large Amounts - Measuring Moisture

- Nut Processing - Large Amounts - Calibrating Nuts

- Nut Processing - Large Amounts - Cracking Nuts

- Nut Processing - Small Amounts - Nut Washing

- Nut Processing - Small Amounts - Nut Calibration

- Nut Processing - Small Amounts - Nut Cracking

Feucht Obsttechnik GmbH products

Nut Processing - Large Amounts - Washing Nuts

Feucht-Obsttechnik - Walnut Washing Machine

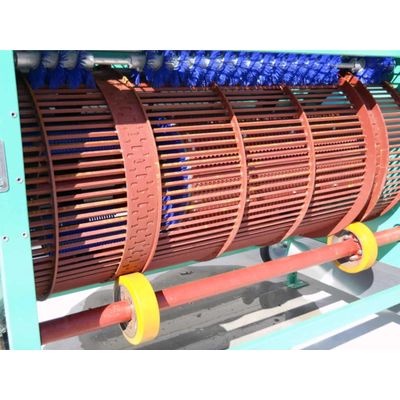

Washing and cleaning walnuts. After the harvesting, the collected nuts should be cleaned of small branches, earth, leaves, and raw shells. The washing machine for nuts is equipped with a rotary drum including stable steel bars. By using water jets in the rotary drum, an efficient cleaning is achieved. We offer various models and sizes according to the extent of the walnut harvest.

Feucht-Obsttechnik - Fruit Harvesting Washing and Calibration Machine

The machine cleans, calibrates, and separates walnuts. The washing and calibration machine cleans and calibrates the nuts according to their size. Up to 95% of the raw shells are separated from the nuts. A washing drum (oval pattern) is used for cleaning. The roller / drum is then exchanged with a round hole sieve for calibrating the nuts. The machine can be calibrated to two different sizes. It is driven by a standard drill. An optional feeding of the nuts or electric motor with 230V is also available.

Feucht-Obsttechnik - Walnut Washing Machine and Raw Shell Remover

Washing nuts and removing shells with a single machine. The walnuts are rotated freely in the rotary drum. The bars of the rotary drum are provided with small brushes and abrasive steel particles (humps) in order to remove the raw shells from the nuts. During the peeling operation a low-pressure water stream in the interior of the drum ensures gentle cleaning. The results are clean, high-quality nuts.