- Wall Formwork - Framed Formwork

- Slab Formwork - Table system

- Slab Formwork - Prob Slab Formwork

- Climbing Formwork

- Wall Formwork - Timber-Beam Formwork

- Farrow Machinery

- Machines for Insemination

- Pigs Breeding

- Manure Removal

- Hygienic Floor Systems

- Livestock Microclimate Control System

- Livestock Feeders and Waterers

Variant Factory Ltd. products

Wall Formwork - Framed Formwork

Variant - Framed Formwork

Frame formwork Varimax by «Variant» Factory Ltd. is a complete system that includes accessories ensuring operation and safety and offering the opportunity to meet any challenges promptly and efficiently.

Slab Formwork - Table system

Variant - Formwork tables

VARITABLE by Variant is a fast and efficient way of forming large-area slabs. The system can be easily adjusted to varying structural and architectural designs (loads, shapes, concrete surface etc.) Once assembled, a complete table unit can be positioned, adjusted, stripped and repositioned to a new area of concrete placement minimal labor. The table can be shifted along the slab using Variant’s shifting trolley. In order to gain maximum efficiency, Varitable can be easily combined with VARITABLE PLUS and VARIFLEX systems.

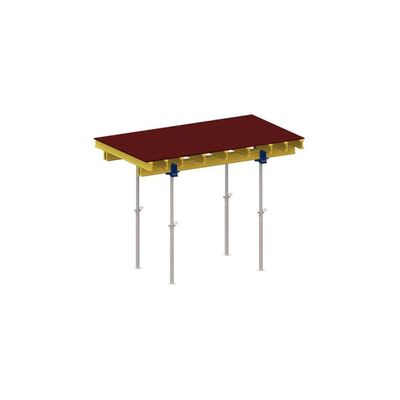

Slab Formwork - Prob Slab Formwork

Variant - Slab Formwork

VARIFLEX by Variant is a conventional prop formwork system for flat slabs forming and shoring. Having only 5 main components, the system is fast and easily assembled, consequently operational time and labor costs are optimized. VARIFLEX adapts to any slab applications due to beams overlap and the fact that the props can be placed anywhere along the main beam. Simply by changing 3 variables (distance between main rows, distance between props in the main row and distance between secondary beams), the system can be applied to any load.

Climbing Formwork

Variant - Climbing Working Platform

CWP system is a reliable combination of Variant’s folding working platforms and framed or timer-beam formwork systems for use as a crane-jumped formwork on sites where the formwork has to be repositioned upwards in several casting sections, and there is no need for retractable formwork. CWP can also be used as a roof and edge protection system.

Wall Formwork - Timber-Beam Formwork

Variant - Large-area Formwork

Easily adaptable system, which solves all requirements for architectural concrete design. Vertex 60 means applications in different type of projects and construction sites. Starting from simple straight walls, complicated column cross-section through residential and high-rise construction up to bridges construction. Also it can be used as formwork shutters for single sided or climbing systems. The standard components of the system such as steel waling`s, H20 beams and flange clamps can be assembled in formwork and customized for a particular project.

Variant - Adjustable Circular Formwork

The circular formwork Ringform by Variant is a practical system for forming of smooth and curved walls. Only 6 types of elements are used: 3 sizes in height 1.2/2.4/3.0 m and 2 widths, 2.4 m for inner part of the wall and 2.5 m for outer. The required radius is easily achieved by using adjustable spindles.

Farrow Machinery

Farrow Machine

There are five positions of the width of box back side 492/530/575/613/658 mm. The length of the box without a feedbox is regulated depending on a sow size (1742…1906 mm). Safety bows. Possibility to regulate the height of the separating bows.

Mounted - Farrow Machine

Possibility to regulate the width (up to 175mm) and the length (up to 350mm). Fastening to the main wall. Non-overturning feedbox. Reliable fixation is provided with the help of a pin on the doors and a plate on the top of the machine. Possibility to open a side wall of the machine. The door leaf can be opened both inside and outside of the machine.

Farrow Machine

There are four positions of the width of box back side 598/648/698/748mm. The length of the box inside without a feedbox is not regulated and is 2014mm. Overturning feedbox with 14liters capacity. Safety and separating bows.

Farrow Machine

There are three positions of the width of box back side 579/628/679mm. The length of the box inside without a feedbox is regulated depending on a sow size (1708…1933mm). Overturning feedbox with 14liters capacity. Safety bows.