- Home

- Companies

- Moving Floor AB

- Products

- Moving Floor Bedding Dispenser

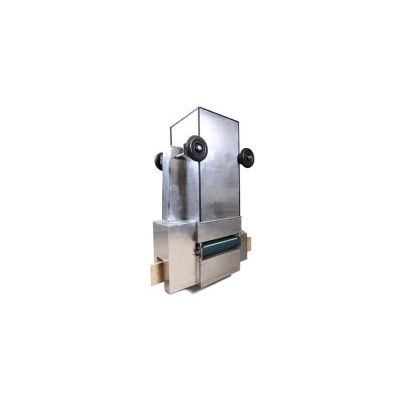

Moving Floor Bedding Dispenser

Moving Floor Bedding Dispenser can easily be installed in new and old barns to streamline the distribution of bedding material. The Bedding Dispenser is programmed in desired interval and bedding material quantity. It ensures that only new, fresh bedding is supplied to the cubicles several times a day. If bedding materials are stored in front of the cubicles the risk of bacterial growth is very high. From an udder health perspective, it is ideal to supply dry bedding material several times a day. And you do not have to do the heavy work yourself …

- The Bedding Dispenser is driven on a wooden plank mounted on top of the loops

- To pass over walkways the Bedding Dispenser uses its patented upper drive

Save time

A lot of time can be saved on handling bedding material. Average time spent per day per cow is 0,18 minutes

Hygienic bedding material

Barn environment is often humid and promotes bacterial growth – for the quality of the bedding material it should be kept dry and brought into the barn often

Small quantities

Program your Bedding Dispenser in desired interval. For the best result we recommend small quantities to be distributed often.

Cost effective

Installation of Moving Floor Bedding Dispenser is easy and cost effective

Measures

- Length: 1000 mm

- Width: 600 mm

- Height: 1200 mm

- Weight: 40 kgs

- Volume dispenser: 250 liters

Material

- Container: Aluminium

- Input: PVC mat with cleat

- Rail: Wooden plank

Installation

- Installation: In new or existing barns. Wooden plank installed on top of loops serves as rail for the machine.

- Refill: Can be equipped with hopper

- Movement: 90 degrees sideways. Bridging rails needed over walkways.

- Electricity: 24 V DC

- Control: PLC

Drive

- Battery: 24VDC with docking station

- Drive: Patented drive existing of double drive. 6-axis drive with chain

- Control: PLC programmed in interval and bedding amount