- Home

- Companies

- Pfanzelt Maschinenbau GmbH

- Products

- Pfanzelt - Model S-Line - Forwarding ...

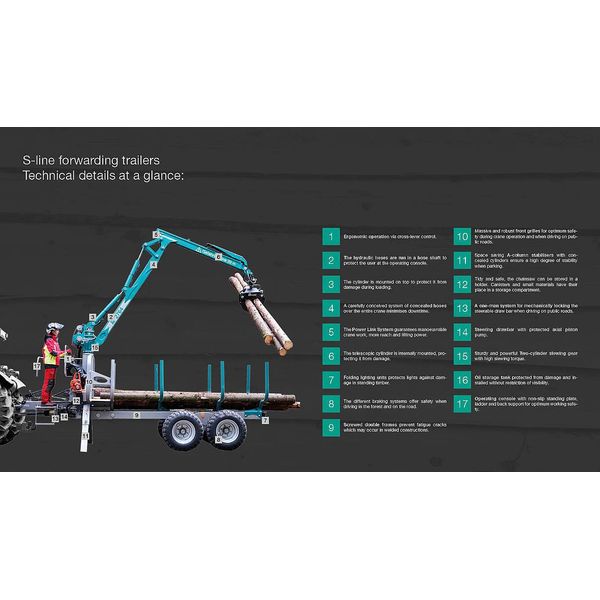

Pfanzelt - Model S-Line - Forwarding Trailers

The Pfanzelt S-line forwarding trailers are especially designed for use by private forest owners and semi-professional operations. The reliability of the technology has the same priority as for professional. However, the job description is different. The Pfanzelt S-line forwarding trailer is especially designed for service with private wood owners and semiprofessional operations. An important criterion when buying a forwarding trailer is the safety equipment. Pfanzelt forwarding trailers offer all safety features required by KWF, FPA and the trade association.

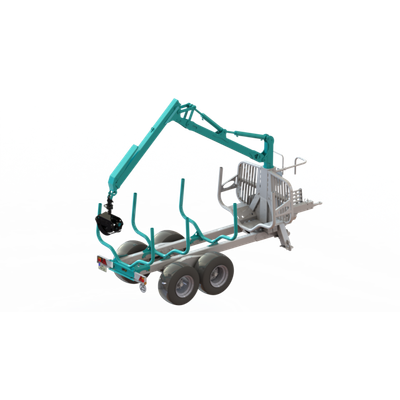

Forwarding trailer S6

The model S6 is the starting model into Pfanzelt`s forwarding trailer programme. A compact forwarding trailer with considerable power.

Forestry farmer Thomas Neuner from Garmisch-Partenkirchen uses his Pfanzelt S-line S6 forwarding trailer in combination with his 60 hp compact Lindner tractor to transport his firewood.

- Load carrying capacity in standing timber of 6 t

- Double frame made of special steel

- Operating permit for public roads

- Modern and powerful forestry cranes

- Independent hydraulic oil supply with protected piston pump installed in the draw bar (optional)

- Accessories for forestry professionals: various braking systems, cuttings tray, crane cable winch

Double frame

The frame of the S-line forwarding trailer is constructed as a bolted double tube frame. In this way, the loading bed can be used flexibly for different trunk lengths. Metre wood can be loaded at right-angles without conversion.

As soon as the two additionally available stanchions are mounted in the rear, the forwarding trailer can also be loaded with metre-wood bundles, or loose metre wood diagonally to the direction of travel.

Bogie axle

The bogie axle provides stability during crane operation and the greatest possible off-road mobility when driving, especiallyoin forwarding tracks. The even distribution of the ground pressure is another big advantage.

Brake system

The S-line forwarding trailers are equipped with a hydraulic 2-wheel braking system as standard.

Road approval for 25 km/h is standard.

Steerable draw bar

The S-line forwarding trailers have a swivelling drawbar with high steering angle as standard. Two powerful hydraulic cylinders facilitate operation even when the laden forwarding trailer is turned against the slope. The steerable draw bar can be mechanically locked when driving on roads.

High-sided floor pan

Optionally, the forwarding trailer can also be equipped with a tray for cut material. It consists of two parts and can be mounted quickly and easily with the crane. The hot-dip galvanised high-sided floor pan is designed for transporting branch and cut material.

DUO Option (tipper bed)

If you also want to transport bulk materials with the S-line forwarding trailer, the DUO variant of the S6 or S8 DUO is recommended. This is designed for versatile use. With the “DUO” option, the forwarding trailer is equipped with a hydraulically tilting dump box. The dump box can be used to transport and dump bulk material. If the two quick-change elements are removed, logs and cuttings can be transported. Side wall extensions are available for transporting branches and shrubs.

LED lighting with indicator monitoring

The lighting system using LED lights is integrated in the frame. To protect the lights when working in the forest, these can be folded in.

Stowage space

Important work equipment such as petron cans or tension belts are always at hand and can be transported safely. A chainsaw holder is also standard.

Crane geometry and ergonomic operation

Crane geometry

The toggle system on the forestry crane – also known as the power link system – between the main boom and folding boom ensures optimum crane geometry for loading work. Ergonomic loading directly onto the front grille is also thus made possible.

Protected from damage when loading and unloading the forwarding trailer, both hydraulic cylinders are located above the main arm. It also ensures constant force, greater reach and a higher working speed.

Ergonomic operation

The Pfanzelt operating station mounted as standard on the draw bar provides a well organised work station outside the hazard zone with an optimum view for safety purposes of the loading crane and the surrounding area. The crane control, which has two cross levers with an electric switch each, enables easy and comfortable crane operation.

Stabilisers

Protected from damage when loading, the cylinders of the A-pillar support are installed inside. The telescopic structure of the stabilisers ensures secure support even in thick stands of timber and on slopes. It also makes it possible to drive close to the polter and thus utilise the full lifting power of the loader crane.

Hose routing

Protected routing of the hydraulic hoses from the control block to the tip of the crane ensures low downtimes and maxises safety at work.

Pfanzelt`s highest priority is to ensure that the hydraulic hoses are secured over the entire crane or installed internally.

Crane winch

The Pfanzelt crane cable winch for the S6 and S8 offers more comfort and safety in use.

- Tractive force 1.5 t, cable capacity 50 m

- Professional forestry radio system

- Mechanical trailing drum brake

- Freewheel for fast and easy cable pull-out