Process Water Articles & Analysis

36 articles found

THE CLIENT The Client is one of world's most important coffee roaster wants to reduce its wastewater disposal costs and one of the market leaders in Italy. The company has eight production sites in the ...

In the dairy processing industry, accurate and reliable level measurement is crucial for ensuring efficient and safe operations. ...

Because of its low calorific value, or because of its different metabolic process from glucose, it can still have some special uses. Non-sugar sweeteners have high sweetness, low dosage, small calorific value, and mostly do not participate in the metabolic process. ...

Clear-water systems usually involve an external biofilter for nitrifying bacteria, and filters for removal of solids from the water (some installations use UV systems for water sterilization). In biofloc technology, the main concept is that the system is designed to benefit bacterial community composition and microbial communities so that they ...

The current trend is to use more and more vegetable proteins and this has an impact on the extrusion process. Normally, when you add more vegetable protein, the process will require more water and the more water in the system, the more energy is needed to perform the cooking, since the water acts as oil and ...

Compared with other methods, it does not require monotonous methods such as fuel oil and gas. Because the monotonous process is omitted, the return ratio is low (accounting for about 15% of the total feed volume of the kneader), the technical process is simple, and the investment is low. ...

Essential for the manufacture of infant formula or beverages, the use of drinking water as an ingredient requires compliance with strict criteria for food safety. In order to comply efficiently with production requirements while guaranteeing the microbiological quality of the water ingredient, Veolia Water Technologies has developed Nurion, a standardized range of plug & play osmosis ...

We collect the organic materials that are discarded in these places, then ferment them with The Groove Type Compost Turner, remove the water, process and mix them into organic fertilizer. Advantages of The Groove Type Compost Turner: The Groove Type Compost Turneris also suitable for aerobic fermentation. ...

How to Speed up Composting Composting is a natural process. You can say it’s the most important recycling process in the ecosystem. ...

Effects Of Feed Formulation On Pellet Durability In Feed Processing Machinery Of course, in the process of using feed processing machinery for production operations. ...

As global demand for milk, cheese, yogurt and other dairy products continues to grow, cost and energy management concerns are driving the introduction of new technologies in dairies to optimize and control costs of water usage. In dairy plants, water usage is one of the major costs in the processing of the milk that is both a direct product and ...

The amount of the sheep manure depends on how much the water content of the sheep manure is determined. According to the fermentation process, the water content is required to be within 45%, that is, the material is kneaded into a mass, and the water can be seen. ...

For more than 20 years, J.W. Treuth & Sons Inc., a kosher slaughterhouse based in Baltimore County, MD, has used a Model 5H from Oil Skimmers Inc. to remove fats, oil and grease (FOG) from kill-floor wastewater. The company recently purchased a new skimmer to replace the original, which, according to Vernon Treuth Sr., he purchased to correct FOG violations — the amounts of fats, oil ...

Factors analyzed include echo reflectivity parameters such as the mean and maximum echo intensity, the anomaly percentage of the grid number of effective echoes, the fractional contribution to the total reflectivities, and the vertically integrated liquid water content (VIL) during and after the seeding process. About 12 minutes after seeding ended, the composite ...

Aquaculture and processing present challenges in terms of water footprint and pollution The seafood industry has been growing around the world, and attention to attendant water issues has been increasing as well. ...

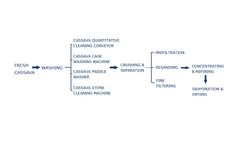

1.Process 2.Production capacity Small-scale processing: 1.5-2 tons / hour, 3-4 tons / hour Medium-scale processing: 5-6 tons / hour, 6-8 tons / hour, 8-10 tons / hour Large-scale processing: 15-30 tons / hour The above processing amounts are based on the amount of processed fresh potatoes per ...

Then, with an innovative membrane filtration installation, the liquid is converted into concentrated organic potassium fertilizer and clean water. The water may be discharged directly into the surface water or possibly used against desiccation or as process water in the industry. Facts and Figures Between 60% ...

The purity of boiler feed water can be a critical part of the manufacturing process. This water needs to be free from contaminants in order for the boiler to operate correctly, without frequent shutdown for maintenance. ...

Delivering water through a spider web of surface channels is a complex manual process. Water levels and releases in each channel had to be balanced so that each customer received their water allotment regardless of their location in the distribution system. ...

People concerned about their water footprint often make an effort to turn the faucet off quickly, take shorter showers, and cut back on watering the lawn. ...