farmatic tank systems products

Biogas Plants

Agricultural Biogas Plants

When planned optimally, agricultural biogas plants perfectly fit into farming and soil nutrition cycles. The anaerobic digestion of manure, agricultural byproducts and energy crops not only provides electricity and usable heat – it also produces a high quality organic fertilizer and soil conditioner.

Biogas Components

Double Helix Manure Heat Exchangers

Double helix heat exchangers are specifically designed for thermal processing of manure, sludge and any other liquid biomass. With the double helix system, cold substrate can be circulated against heated substrate for heat recovery purposes. This makes our double helix heat exchanger system optimal for economical hygienisation and pasteurisation, heat recovery and for external heating systems for biogas digesters with estremely low energy loss.

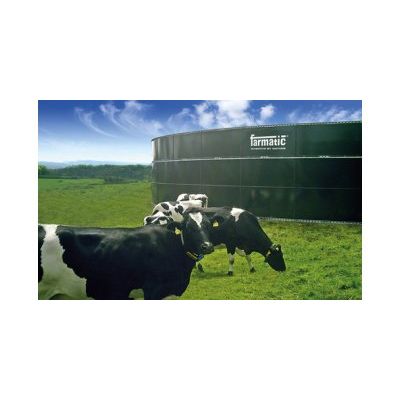

Agricultural Storage Systems

Farmatic - Slurry and Storage Tanks

FARMATIC slurry tanks are offered in various individual sizes. They guarantee secure storage at low cost. Additionally, their longevity and easy expansion or disassembly make them the moste flexible choice when it comes to liquid storage for decades.

Storage of Sugar Beet Pulp

Sugar beet roots are a biogas input material that is very demanding on storage tanks. During ensilage in the storage tank, the beet pulp has a pH value of 3.2 – 3.7. FARMATIC’s highly resistant enamelled steel tanks are the optimal solution for hassle-free beet storage.

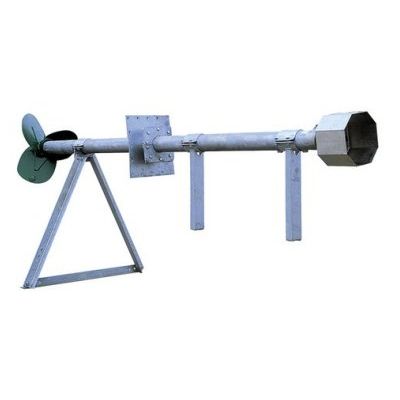

Farmatic-Jet - Fixed Slurry Mixer

For tractor power take-off. With power exceeding 50 kW, additional vibration dampener and gasket provided. Secure installation on the tank foundation with two steel bars. Externally mounted on a concrete socket that also serves as collision protection for the tank wall.

Farmatic - Turbobooster - Fixed Slurry Mixer With Directional Booster

Extremely effective for dissolving thick floating layers and sediments. No external foundation socket necessary. Secure installation on four steel beams. Jet direction can be altered variably in 360° by rotating the mixer. Installation height 500-1500 mm.