Fertilizer Granulation Process Rotary Drum Articles & Analysis

38 articles found

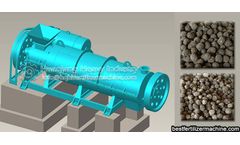

Create extrusion force to agglomerate into spheres. Related post: organic fertilizer granulator machine The personnel of Richi Equipment has gathered many years of experience in the manufacturing of compound fertilizers, and the rotary drum natural fertilizer granulator device ...

The compound fertilizer drum granulator includes a rotary drum, a drive motor that drives the rotary drum to rotate, and a spray pipe arranged in the inner cavity of the rotary drum. ...

The disc granulator adopts an overall circular arc structure, and the granulation rate can reach more than 93. The disc granulator is composed of a large plate, a large gear, a transmission part, a frame, a base, a scraper frame, and a non powered scraper. The structure of disc granulator is novel and reasonable, and its weight and height are reduced. The process layout is flexible and ...

Here, two kinds of common granulator equipment are introduced. Bio organic fertilizer granulation machine How does the organic fertilizer equipment disc granulator process granular fertilizer? ...

The new type of organic fertilizer granulator machine is mainly used for the granulation of all kinds of organic materials after fermentation. It breaks through the conventional granulation process. Before granulation, the materials do not need to be dried. ...

The characteristics of the double roller granulator are destined to have a primary low position in the production of compound fertilizer. The advantages of the roller granulator in the compound fertilizer production technology are energy saving and consumption reduction. The extrusion granulation is to granulate the material at room temperature. Compared with other methods, it does not require ...

In order to increase the production scale and improve the quality, the factory must add the production equipment of chicken manure organic fertilizer. The horizontal mixer of the production equipment of organic fertilizer can make the microbial bacteria evenly mixed in the chicken manure and other raw materials. After the organic fertilizer is fully fermented by the organic fertilizer dumper, the ...

Granulation A new type of organic fertilizer granulator machine was used to granulate the materials. 4. ...

The flat die organic fertilizer granulator machine is cone-shaped. It makes the linear speed of both ends of the die consistent with the inner and outer ring of the die disc, avoids the dislocation friction between the wheel and the die, reduces the resistance, reduces the kinetic energy loss, and prolongs the service life of the die, which is a significant difference from similar compression ...

At present, there are various organic fertilizer materials, such as: disc pelletizer, flat die pellet mill, new type organic fertilizer granulator, rotary drum granulator, extrusion granulator, etc. ...

What should we pay attention to when raising rabbits? Do you know? The following rabbit manure processing organic fertilizer manufacturing process Huaqiang equipment manufacturers to summarize a few points, hope to help. 1. It is important to provide a comfortable environment and ensure a normal diet for rabbits. The rabbit is relatively timid. The quiet and leisurely environment can help the ...

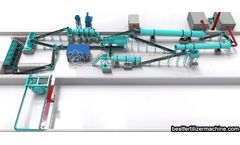

NPK fertilizer drum granulator has the characteristics of uniform granulation, high granulation rate, stable operation, strong and durable equipment, long service life and so on. It is the ideal equipment for the majority of users. Working principle of rotary drum npk ...

Huaqiang compound NPK fertilizer granulator was used for fertilizer production. After the material enters the drum body, it moves up and down under the action of gravity, centrifugal force and friction between the materials until it reaches the required particle size and overflows from the outlet. Characteristics of NPK granulator for Huaqiang compound fertilizer 1. The drum granulator has the ...

Here we will explain to you the granulation equipment in a very widely used pelletizer - rotary drum granulator. ...

What are the granulators of organic fertilizer granulation process? 1. Agitator granulator Stirring teeth granulator is through high-speed mechanical stirring to produce aerodynamic force, so that the fine materials can be mixed into granules in the granulator. ...

NPK fertilizer granulator is the most widely used granulator in organic fertilizer and pulverized coal granulation. The design of NPK fertilizer granulator is very reasonable, fertilizer granulator machine price concessions, practical and energy consumption is very low. It can be continuously produced at room temperature without drying. It can make the ball and socket on the roller skin according ...

Huaqiang factory's fertilizer equipment drum granulator solves the problem of wall sticking. The fertilizer drum steam granulation manufacturing process has large output flexibility. Rotary drum granulator is cylindrical and has ...

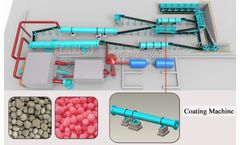

It is different from the compound fertilizer rotary drum granulator processing technology. Why to use sulphur coated urea fertilizer 1. Sulfur-coated urea can improve the fertilizer utilization rate, which is similar to the granular fertilizer made by the disc ...

In the NPK fertilizer manufac?turing process, a coating process is added to make a slow-release fertilizer. Slow-release fertilizer is also called controlled-release fertilizer. The release rate of nutrients in fertilizers can be controlled to a certain extent for continuous absorption and utilization by crops. After the fertilizer is coated, it can reduce the loss of fertilizer nutrients, ...

The qualified pelletizing rate of disc granulator is as high as 80-90%, which is suitable for a variety of different formulations. The rate of big ball is less than 15%. The uniformity of particle size can be adjusted by stepless speed regulation function of the machine according to the requirements of users. This organic fertilizer granulation machine is suitable for direct granulation after ...