Agricultural Industry Equipment

-

ShowcaseManufactured by Farmcomp Oybased in FINLAND

Wile 500 is a modern, precise and durable moisture and temperature meter for baled hay, haylage, straw and silage. You will no longer need separate moisture and temperature meters, instead you can measure temperature and moisture content easily with one and the same ...

-

ShowcaseManufactured by Mosa Green S.r.lbased in ITALY

Special applications of rails and trolleys mounted on the existing heating pipes of the greenhouse, instead of the rails supplied with the Mosa system. The tailor made system will also fit inside the lighting systems of the greenhouses and the water supply hoses can be of the size of 1” or 1” 1/4 inch. ...

-

ShowcaseManufactured by AFKO Ltd. Şti.based in TURKEY

This system consist of many spans connected to each other by mobile connection, all spans move and rotate around a fixed center. Every two spans are connected by a multidirectional joint allowing the formation of an angle of up to 30 degree. Thus the pivot is suitable for rough terrain. This system irrigates from 1 hacter by one span up to 75 by 8 spans 490 m machine. ...

-

ShowcaseManufactured by Jenfitch INC.based in USA

One of the major issues facing citrus fruit growers is a disease that effects the trees called citrus cankers. JC9450 has been used to effectively control the growth and infectious nature of citrus cankers. By increasing the oxidative energy in the root system and around the leaf & stem area, JC 9450 will fortify the plant’s natural resistances and healing properties by increasing the ...

-

ShowcaseManufactured by Ecological Laboratories, Inc.based in USA

Modern Bio Technology for Enhanced Manure Management Specially formulated for manure pits over slatted floors, outdoor manure lagoons and vertical holding tanks. Non-GMO, nonpathogenic, highly active cultures and enzyme formulation designed to liquefy, activate and enhance manure value and create bio-active manure slurry beneficial to all plants and ...

-

PremiumManufactured by Varicon Aqua Solutions Ltdbased in UNITED KINGDOM

We can supply live algal cultures in a variety of formats, from agar plates to multiple litres of volume. This service will save the end user having to sub-culture master stocks in the ...

-

PremiumManufactured by Delta-T Devices Ltd.based in UNITED KINGDOM

The ML3 ThetaKit provides researchers with a portable tool for highly accurate, near instantaneous measurement of moisture levels in soils and substrates. The ThetaKit is easy to use. Simply switch the connected HH2 Moisture Meter on, insert the probe pins fully into the soil, and press the HH2’s “read” button to display the moisture measurement. Readings can then be stored with ...

-

PremiumManufactured by Ligapal Sarlbased in FRANCE

The Distriliens LIGAPAL is a cardboard distributor of ready-to-use links. 100% biodegradable ties for tying the vine. The Distriliens contains 1000 ties of LIGAPAL paper-steel twine pre-cut in 15cm length (possibility of having 12 cm, consult us for ...

-

PremiumManufactured by Ligapal Sarlbased in FRANCE

This aphrometer is designed to check the pressure during the secondary fermentation. This Champagne pressure gauge checks instantaneously the pressure in the bottles topped on with a crown cap with or without plastic ...

-

PremiumManufactured by Matthews Environmental Solutionsbased in USA

The Matthews Environmental Solutions range of Surefire SA fixed hearth pet cremators are internationally acclaimed as the most effective and environmentally responsible pet cremator systems available today. They are also highly regarded for the quality and respect they afford to each individual pet owner. The horizontal cylindrical design offers the strongest possible refractory construction ...

-

PremiumManufactured by Ecological Laboratories, Inc.based in USA

Our hi-count (20B-CFU/g) is a highly mobile, feed additive and water treatment product formulated to promote the production of healthy shrimp and fish. Microbe-Lift / DFM Microbial Blends are a cost effective and environmentally friendly option to manage Aquaculture Systems that often struggle with the overstocking of farms and the creation of excess waste. There is a strong correlation between ...

-

PremiumManufactured by Falcon Srlbased in ITALY

Features: For Æ 60 transport systems. Capacity: 7 liters. Transparent container in Polypropylene. Porthole for clearing. The ball which opens the dispenser guarantees a smooth action to give simultaneous distribution of all the feed from each dispenser. Cord in stainless steel. Possibility of exclusion of each dispenser by single shutter. Can be supplied ...

-

PremiumManufactured by Falcon Srlbased in ITALY

Features: Æ 60 transport systems. The shape of the drop tube guarantees the absence of residual feed between the pipe and the shutter. Automatic control of the shutter: the dose regulation or the exclusion of the dispenser can be made by PC. Container with different sizes up to 22 liters. Simultaneous opening of all the dispensers by ...

-

PremiumManufactured by Matthews Environmental Solutionsbased in USA

The Matthews Environmental Solutions range of Surefire SA fixed hearth pet cremators are internationally acclaimed as the most effective and environmentally responsible pet cremator systems available today. They are also highly regarded for the quality and respect they afford to each individual pet owner. The horizontal cylindrical design offers the strongest possible refractory construction ...

-

PremiumManufactured by Reef Industries, Inc.based in USA

Reef Industries' Plastic liners play an important role in fish hatcheries and aquaculture farms by providing reliable containment for bodies of water such as ponds or tanks. These serve as a barrier that prevents water from seeping into the ground and ensures the management of water ...

-

PremiumManufactured by Falcon Srlbased in ITALY

Direct extraction from the silo. Chain or spiral feeding systems 0 60. No waste stainless steel cup-shaped manger. Complete ...

-

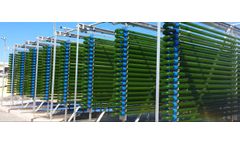

PremiumManufactured by Varicon Aqua Solutions Ltdbased in UNITED KINGDOM

The Phyco-Flow photobioreactor is an innovative serpentine system that scales easily to meet increased production requirements at both pilot and commercial scales (0.6 – 30 m3 in volume). This configuration has superseded our BioFence photobioreactor and offers numerous operational improvements. This includes lower capital and operational costs, and reduced shut down time via an integrated ...

-

PremiumManufactured by Cloud Tech Pvt. Ltd.based in INDIA

Cloud Tech Pvt. Ltd. is End to End customized solutions company, we believe in nature, which provides solution for Odour, Mosquitoes and bug control system, Humidification control, Outdoor and Indoor cooling, Dust Suppression, etc. We are the only company in the world that uses Natural essential oils formulation which is non toxic, biodegradable, very safe for humans. The solution is not only ...

-

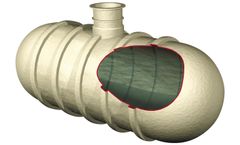

PremiumManufactured by Kingspan Klargesterbased in IRELAND

Our below-ground Cesspools and Silage Tanks provide a reliable solution for the collection and retention of sewage, surface water, veterinary/animal waste, firefighting reservoirs and rainwater harvesting ...

-

PremiumManufactured by Feucht Obsttechnik GmbHbased in GERMANY

The machine cleans, calibrates, and separates walnuts. The washing and calibration machine cleans and calibrates the nuts according to their size. Up to 95% of the raw shells are separated from the nuts. A washing drum (oval pattern) is used for cleaning. The roller / drum is then exchanged with a round hole sieve for calibrating the nuts. The machine can be calibrated to two different sizes. It ...

Need help finding the right suppliers? Try XPRT Sourcing. Let the XPRTs do the work for you